Collision repair safety standards are indispensable guidelines for technician training, prioritizing worker and customer protection. They cover various aspects of repairs from hazardous material management to containment measures, enabling precise and expert execution on classic and modern cars like Mercedes-Benz. These dynamic standards enhance training programs, ensuring technicians are equipped to handle diverse damage from minor dents to complex structural issues while maintaining safe workshops through equipment maintenance, protective gear use, and adherence to protocols for tasks such as auto glass replacement, ultimately benefiting the industry and public.

Collision repair safety standards serve as the bedrock for technician training, ensuring that professionals in this field are equipped with the knowledge and skills to handle complex tasks safely. These standards guide educational curricula, covering everything from personal protective equipment to hazard communication. By adhering to these guidelines, training programs equip technicians with the ability to navigate workshops securely, ultimately leading to safer work environments and improved vehicle restoration outcomes. Understanding and implementing collision repair safety standards are vital for both technician development and workshop efficiency.

- Understanding Collision Repair Safety Standards: The Cornerstone of Technician Training

- How Safety Standards Guide and Enhance Technical Education

- The Impact: Better Trained Technicians and Safer Workshops

Understanding Collision Repair Safety Standards: The Cornerstone of Technician Training

Collision repair safety standards are the bedrock upon which technician training is built, ensuring that professionals in this field adhere to rigorous protocols designed to safeguard both workers and customers. These standards encompass a wide range of considerations, from proper handling of hazardous materials to implementing effective containment measures during repairs. By understanding and embracing these guidelines, technicians can effectively navigate the complexities of collision repair, whether they’re engaged in classic car restoration or handling modern Mercedes-Benz repairs.

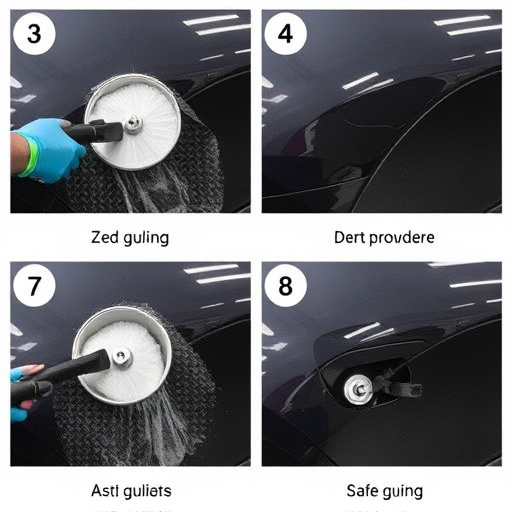

The integration of safety standards into technician training is crucial for several reasons. Firstly, it minimizes the risk of accidents and injuries, which are significant concerns in an environment teeming with potential hazards, such as sharp metal edges, toxic chemicals, and complex machinery. Secondly, adhering to these standards promotes a culture of quality and precision, ensuring that every repair job—from minor dent repairs to extensive vehicle body replacements—is carried out with the utmost care and expertise.

How Safety Standards Guide and Enhance Technical Education

Collision repair safety standards play a pivotal role in guiding and enhancing technical education for technicians in auto body services and collision centers. These standards are meticulously designed to ensure that every professional involved in car damage repair receives comprehensive training on best practices, safety protocols, and modern techniques. By adhering to these guidelines, learning programs can be structured effectively, focusing on not just the technical aspects but also the critical safety measures required in a collision repair environment.

This structured approach ensures that technicians are well-prepared to handle various types of car damage repair, from minor dents to complex structural repairs. It empowers them to work efficiently while prioritizing their own safety and that of others around them. As the world of auto body services continues to evolve with advancements in technology and materials, collision repair safety standards remain a dynamic reference point, keeping training programs up-to-date and relevant.

The Impact: Better Trained Technicians and Safer Workshops

Implementing robust collision repair safety standards plays a pivotal role in enhancing technician training and fostering safer workshops within the automotive industry. When these standards are meticulously adhered to, it sets a foundation for competent and skilled technicians who possess not just technical prowess but also a deep understanding of safety protocols. This leads to improved work quality, reduced errors, and enhanced efficiency in vehicle body shop settings.

Furthermore, these safety standards contribute significantly to the well-being of workshop environments by ensuring proper equipment maintenance, adherence to safety guidelines for tasks such as auto glass replacement, and the use of appropriate protective gear during dent repair processes. As a result, technicians are better equipped to handle complex repairs, fostering an atmosphere where both excellence in work and safety are prioritized, ultimately benefiting both the industry and the public.

Collision repair safety standards serve as a foundational framework for technician training, ensuring that professionals in this field are equipped with the knowledge and skills to perform tasks safely and effectively. By adhering to these standards, technical education programs can guide students through best practices, risk mitigation strategies, and proper use of equipment, ultimately leading to better-trained technicians and safer workshops. This holistic approach not only enhances the quality of collision repair services but also contributes to a more secure environment for both workers and clients alike.